In 2025, a grocery chain client came to us with a clear goal. In one month, make first aid and AED readiness consistent across all locations and easy to maintain.

They were dealing with one of the most common challenges we see with multi-location businesses: inconsistency.

- Different first aid kits at different sites.

- Supplies and AEDs stored in different places.

- No clear system for inspections or restocking.

- No real standardization overall.

Unlike many who ignore these issues, they wanted to improve.

This is how we did it.

Step 1: We Listened

First, we listened. Then we asked questions, and listened again.

We took the time to understand their locations, their risks, and how their teams actually operate day to day. That informed everything that followed.

We didn’t come in with a cookie cutter solution. We came in with questions. What does a typical shift look like? Where do emergencies usually happen? Who’s responsible for safety checks? What’s getting in the way of maintaining readiness right now?

The answers shaped our entire approach.

Step 2: We Standardized the Equipment

Next, we standardized the equipment across all locations.

Same kits, same contents, same layout. We made sure items were easy to find and use under pressure. No more hunting through cluttered bags wondering if the right supplies were even there.

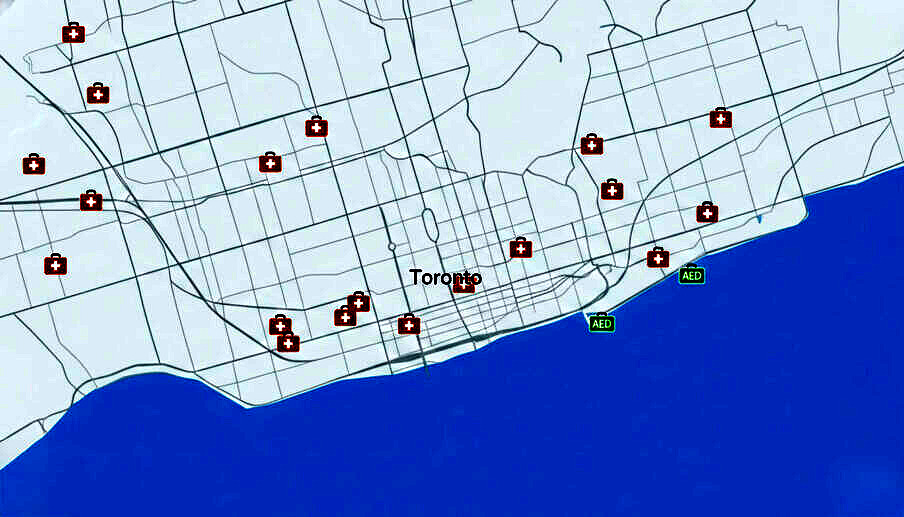

Smart AED placement. We didn’t just pick spots that looked good on a wall. We placed AEDs where they made sense for each space based on foot traffic, accessibility, and proximity to high risk areas.

Consistent labeling and storage. Everything had a designated spot. Staff didn’t need to guess where things were or what belonged in each kit.

When everything looks the same across locations, training becomes easier. Maintenance becomes easier. And in an emergency, there’s no learning curve.

Step 3: We Built a Simple Maintenance System

Then we focused on maintenance and inspection.

We designed a simple, repeatable process so staff could quickly inspect kits, identify missing items, and keep everything stocked.

No guessing. No digging through cluttered bags. Just clear organization and consistency.

The system didn’t require extra meetings or complicated checklists. It fit into their existing routines. Staff could complete inspections in minutes, flag what needed restocking, and move on.

Because if a maintenance system is complicated, it won’t get done. And if it doesn’t get done, readiness falls apart.

The Result: From Compliant to Confident

The key result for them was confidence.

They had already been compliant. But never confident.

Now, staff knew what they had. They knew where it was. And they knew it would be ready if they ever needed it.

That shift from compliance to confidence is what makes the difference in a real emergency. Compliance checks a box. Confidence means people are actually prepared to act.

The Lesson: Preparedness Scales When It’s Simple

The biggest lesson from this project is that preparedness scales across a company best when it’s simple and standardized.

The fewer variations you have, the easier it is to maintain readiness across multiple sites. When every location operates the same way, training transfers. Knowledge transfers. Confidence transfers.

With the right plan, first aid readiness can become part of your operations instead of an ongoing headache.

We Build Systems That Work in Real Life

At First Aid Canada, we help organizations build systems that work in real life, not just on paper.

If your business is dealing with inconsistent first aid readiness across locations, or if you’re not sure your current system would actually hold up in an emergency, we can help.

Get in touch. Let’s build something that works.